Kingdom strives to offer a safe and unharmful working environment to its employees. In addition to the establishment of labour safety and hygiene management regulations, Kingdom has also implemented stringent hardware and equipment standards and safe and hygienic operation procedures in order to give Kingdom’s staff a safe and healthy working environment. All employees are required to attend relevant training before reporting duty, and follow-up training is provided to staff so as to prevent any accident from happening during their work.

To ensure a safe and hygienic environment effectively and consistently, suitable precautionary or necessarycontrol measures have been undertaken. The existing protective measures for areas that show potential risks after evaluation are also reviewed immediately to facilitate quick improvement work or management projects or strengthen response ability with the aim of ensuring that the safety and hygiene conditions of Kingdom’s working environment meet national standards.

Fire drill

Working Safety

Kingdom considers the safety of its staff’s working environments a matter of the utmost importance, and has conducted frequent work safety checks, including routine patrols by supervisors, frequency check and improvement procedure check. Kingdom also requires officers of different ranks under each department to participate in safety training and industrial safety campaigns, and to promote safety awareness and safety monitoring procedures and projects to staff of each levels. Defects are rectified through tracking the information system which allows early identification of potential risks and dangerous behaviour so as to prevent accident from happening, implement safety behavioural work at full speed and enhance work safety performance.

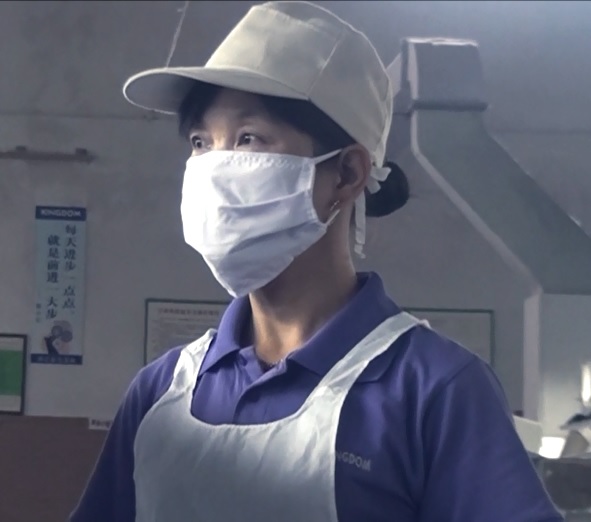

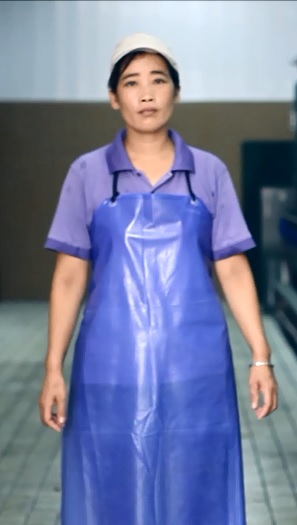

Occupational Health

Kingdom principally engages in linen yarn production which requires contact with chemicals and utilities such as water and electricity. It acknowledges the importance of staff safety and health in the production process and strives to improve personal protection during operations. Operation staff are required to wear protection gears such as safety hats, dust masks and waterproof aprons. Protection reminders are shown at each work zone, and first-aid kits are available at every workshop. Any employee who gets ill or is injured at work will be taken to designated hospitals in the locality for treatment within 30 minutes. In order to promote health awareness, pre-employment health assessment is provided for new employees, and free regular check-up and healthcare seminars are organised for all staff.